In logistics, a few common mistakes can sometimes make the difference between being great and being bad. These not only cause delays, but they also damage trust, raise costs, and slow down progress. But every time anything goes wrong, it’s also a chance to learn and get better. Here are seven common mistakes in logistics and the important lessons they teach:

1. Not enough planning and predicting

If you don’t plan for demand, peak seasons, or disruptions, you’ll have to react instead of plan ahead. If you don’t plan ahead, you’re planning to fail. Use data to plan ahead and make plans.

2. Not using technology and automation

Sticking to old-fashioned ways in a digital age slows down growth. Real-time and automated systems are now the norm; they are no longer optional. Technology is like a friend to you. Embrace it to improve the quality, intelligence, and efficiency of your work.

3. Lack of openness and communication

When communication breaks down, whether it’s between people inside or outside the company, it leads to confusion, missed deadlines, and unhappiness. Clear communication builds trust. Spread information quickly and accurately.

4. Not paying attention to last-mile delivery

No matter how well other parts work, the customer mostly remembers the final delivery experience. The end tells you how well you did. Make sure the end part is smooth and looks professional.

5. Ignoring compliance and paperwork

If you don’t follow the rules or don’t have all the paperwork in order, your business could come to a sudden stop. Following the rules protects your business. Keep records that are clear, current, and correct.

6. Not paying attention to the people involved in the process

Logistics depends on people like drivers, couriers, handlers, and customer service reps. If you don’t pay attention to them, mistakes will get worse. People are what drives the mission. Teach them, recognize what they’ve done, and put money into their growth.

7. Not checking on performance and acting on feedback

You can’t get better without measuring. Not keeping an eye on key performance indicators (KPIs) and getting feedback from customers and staff might lead to problems that go unnoticed. Ignoring the feedback you get is far worse. Feedback is a useful thing to have. To get better results, evaluate performance, listen carefully, and reply quickly.

Finally, logistics is more than just moving things around. It is a way of planning, staffing, carrying out, and being right. By avoiding these seven mistakes, you will not only make your operations run more smoothly, but you will also set up a logistical system that guarantees excellent delivery.

_______________________________________Akinfolami Akinrimisi is a strategic logistics and supply chain professional with a strong focus on warehousing, fleet operations, and performance optimization. He is experienced in driving operational efficiency, managing complex distribution networks, and leveraging technology for business improvement. Akinfolami is results-oriented, detail-driven, and passionate about building systems that enhance service delivery and business growth. Akinfolami is a senior executive at one of the foremost global logistics companies. Email: talk2folami@gmail.com LinkedIn: https://www.linkedin.com/in/akinfolami-akinrimisi-2b40a495

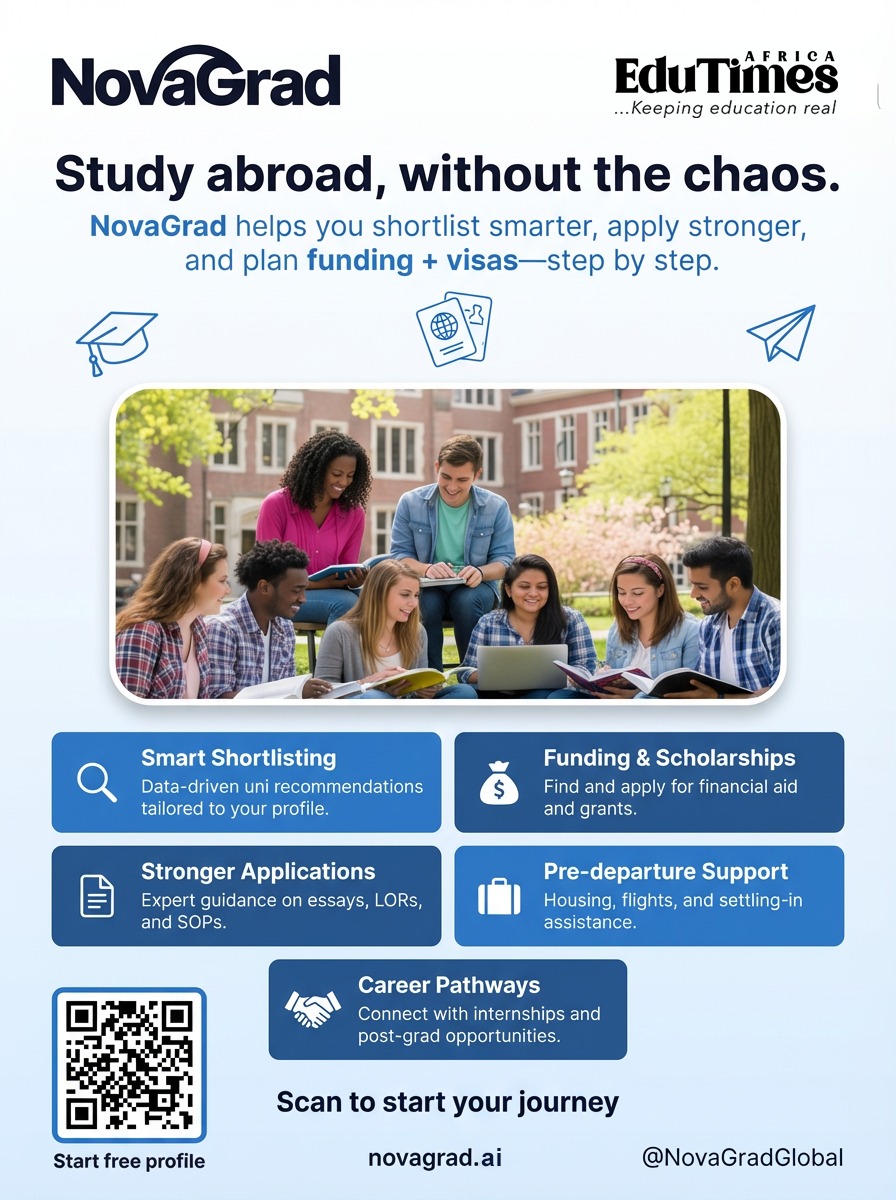

EduTimes Africa, a product of Education Times Africa, is a magazine publication that aims to lend its support to close the yawning gap in Africa's educational development.

EduTimes Africa, a product of Education Times Africa, is a magazine publication that aims to lend its support to close the yawning gap in Africa's educational development.